Background

Alabama Power, one of three Southern Company electrical utility subsidiaries, has a generating capacity of over 13,000 MW, serving in excess of 1.5 million customers via 78,000 miles of transmission and distribution lines. To maintain a competitive rate structure, Alabama Power continues to add to its long history of continuous improvement, searching for enhanced efficiencies in all areas of their business. A significant number of these improvements come from employees, who identify solutions and work with suppliers to realize their potential value add.

With the increased usage of large equipment, such as dead tank circuit breakers, storage was becoming a significant issue for Alabama Power, who was now faced with the need to optimize their existing storage space while also insuring that there were no material shortages when shipping major equipment to job-sites.

Solution

In 2015, Derek Largin, a storeroom materialman at Alabama Power Company, recognized the inefficiencies surrounding the storage and transport of their dead tank circuit breaker inventory. Teaming up with engineer Neil Hutchins (currently an Equipment Services Supervisor for Southern Company), Largin was able to propose and implement a unique design, now known as the Largin Lift System, to address his concerns. This new lift system resulted in the reduction of storage space required for each breaker, guaranteed that there were no equipment shortages at job sites, and allowed the circuit breaker to be transported using a forklift, eliminating the need for a crane. Using a forklift allows for transportation in all weather conditions and also reduces the potential safety hazards associated with the use of a crane.

Largin’s method involved the creation of a shipping platform that would carry the breaker and all associated equipment, supplied by the manufacturer, which would be required for installation. The platform was painted steel and utilized strategically placed tubular channels for support. The forks from the forklift would slide into the tubular channels for lifting, resulting in a balanced lift with little risk of slippage during movement. This simple approach was now a one-man job, significantly reducing the time needed to move these breakers and assuring that all associated materials were not separated inadvertently. Additionally, the lift system utilized steel components, kept units off the ground, and stored accessory parts in watertight, environmentally resistant buckets that diminished long term storage impact. This success using the Largin Lift System for circuit breaker applications ultimately led to its adoption with other equipment.

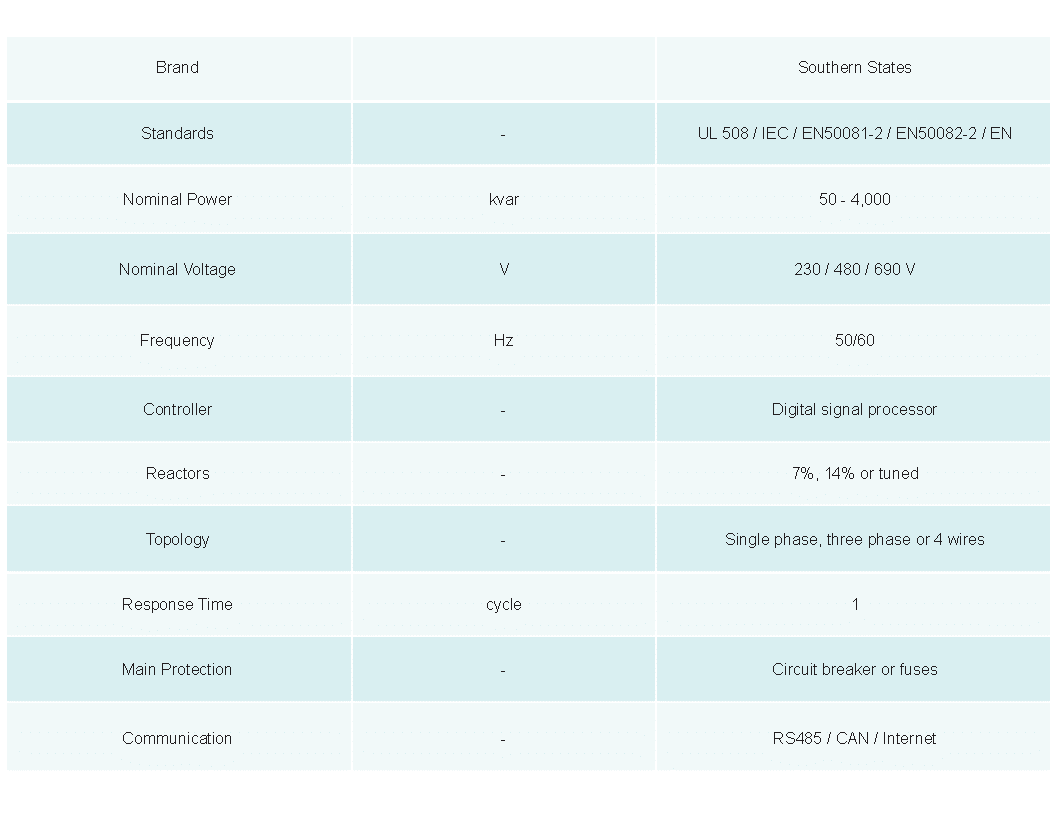

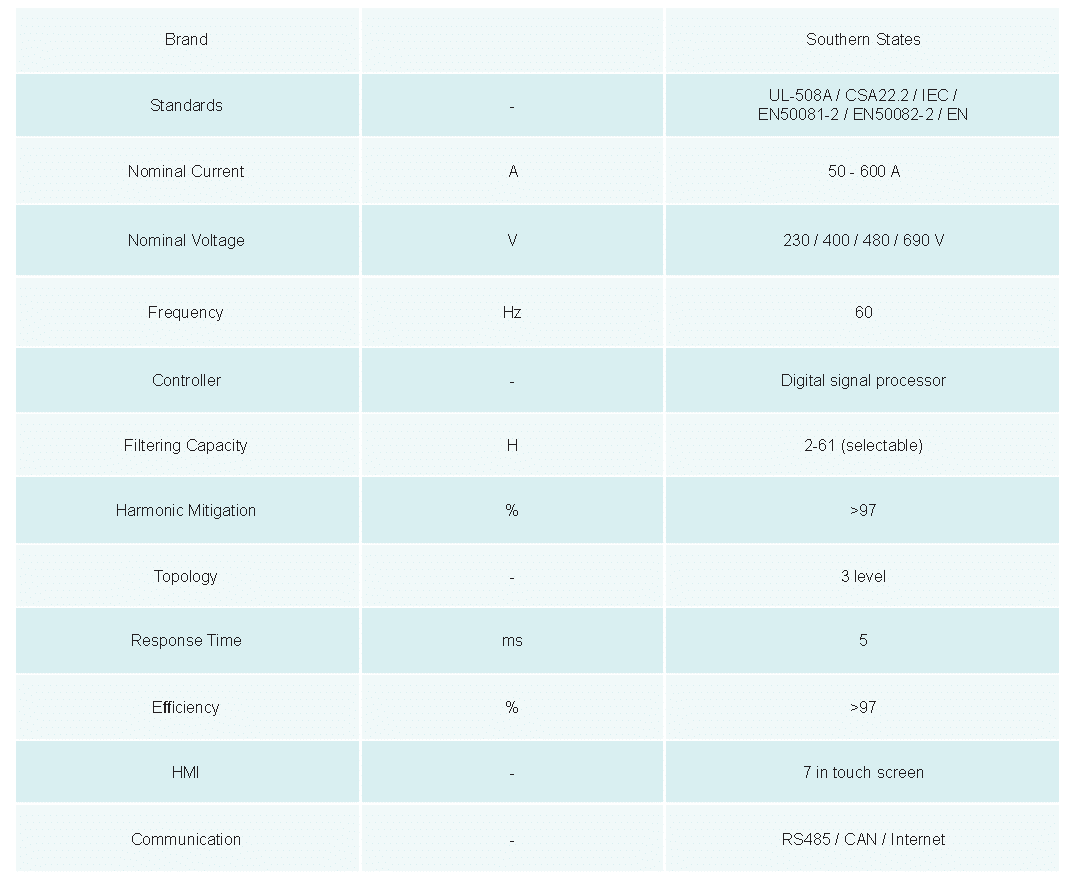

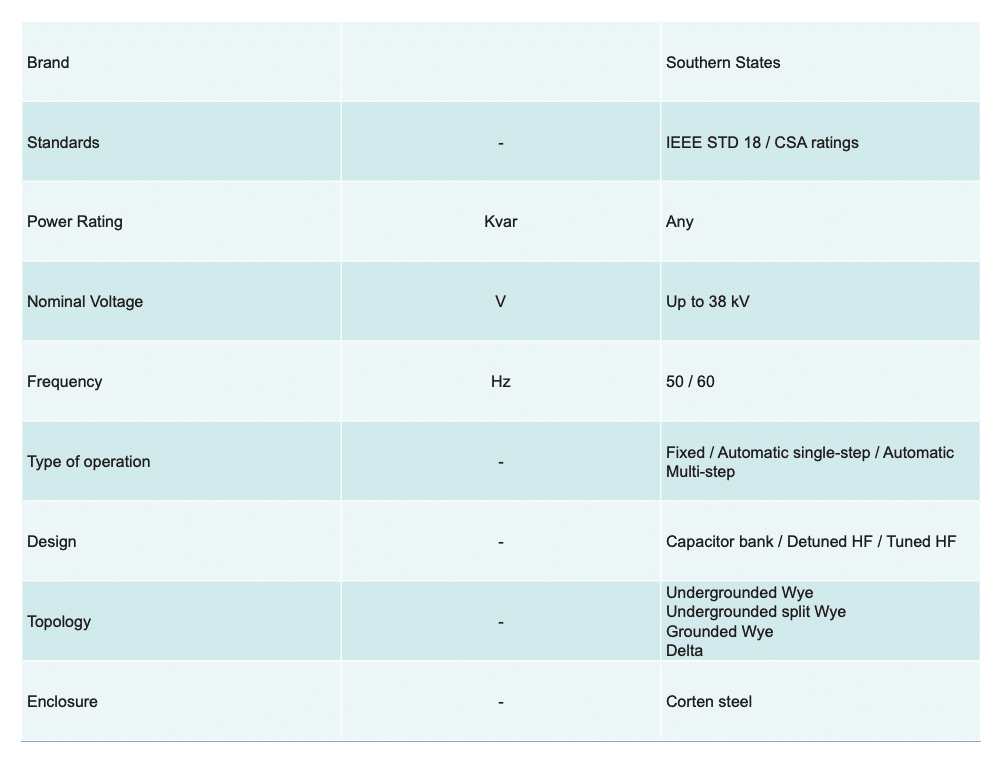

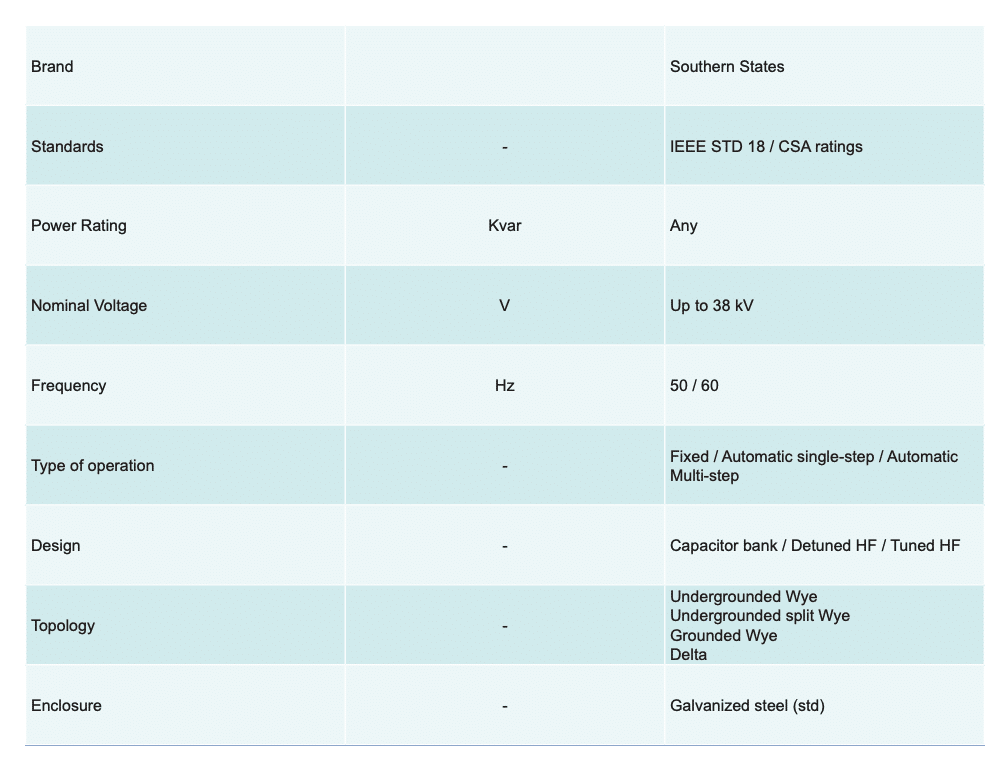

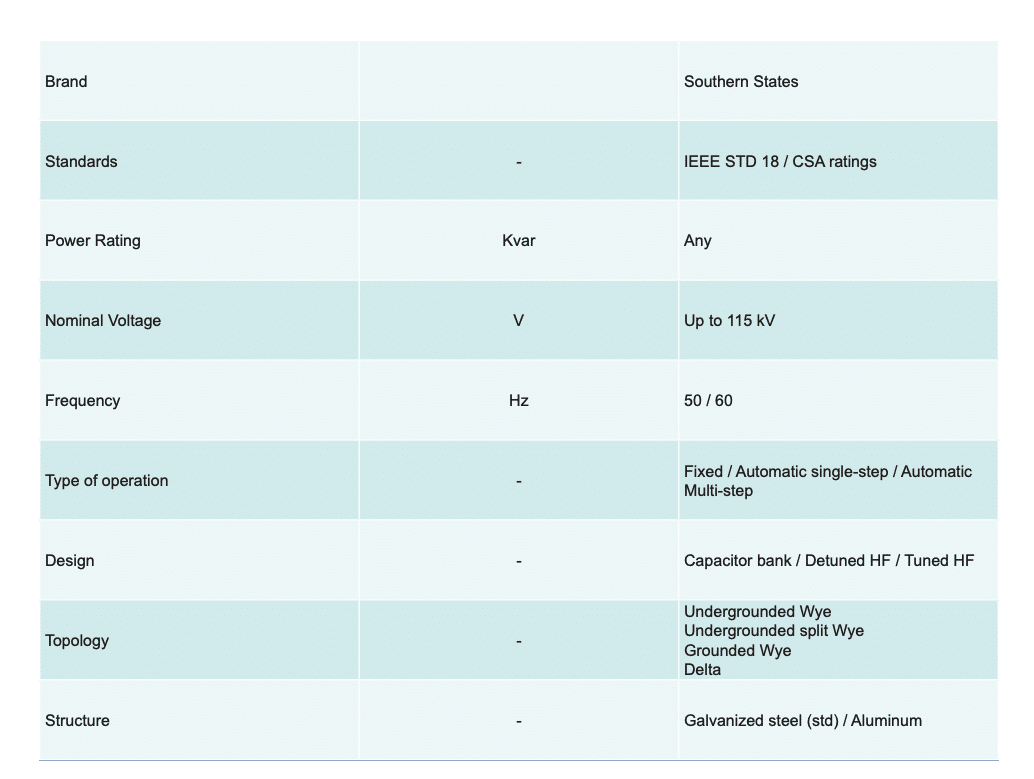

Southern States, a supplier of circuit switchers, capacitor switching products, and disconnect switches to Alabama Power was asked to develop a packaging solution that met the requirements of the Largin Lift System for their supplied products. In response, Southern States designed a unique packaging solution for their live tank products. The packaging includes a steel shipping platform that has bolted, color coded steel members for main components (mechanism, interrupter pole units, control cabinet, support columns, integrated disconnect switches, etc.) and watertight buckets for smaller accessory items. The platform is mounted to two tubular support channels sized and positioned to allow for safe lifting of all material by a forklift. Since all materials required for installation are included as part of the solution, there is no risk of misplaced materials during movement at the storage facility or during transport to the job site.

Results

Southern States helped to expand the use of the Largin Lift System at Alabama Power by developing these unique packaging solutions for their circuit switcher (CSV & CSH) and CapSwitcher® products. As a result, Alabama Power was able to improve storage space utilization, minimize equipment shortages at installation sites, minimize concerns with long term storage, and eliminate the need for a crane to transport these products.

“We’re happy with the engineering support we received from Southern States as we designed the Largin Lift System around their products. Their responsiveness to our needs has been top-notch, and Alabama Power is thankful to have worked together, with Southern States, on this project.” – Neil Hutchins, Equipment Services Supervisor at Southern Company.